Embedded systems drive technological innovations across various sectors, including consumer electronics, industrial automation, and IoT ecosystems. As industries evolve, the demand for efficient, secure, and scalable embedded system solutions grows, making the design process crucial. The development of embedded systems involves key stages, such as system architecture, hardware/software development, integration, testing, and production.

Emerging technologies, such as 5G connectivity and System-on-Modules (SoM), along with advanced engineering principles, are transforming the design and deployment of these systems. These innovations support real-time communication, enhanced processing power, and modularity, meeting the growing needs of modern industries.

This blog will explore the complete embedded system design process, focusing on essential phases, challenges, and technological trends shaping the future of embedded engineering.

Understanding Embedded System Design

Before diving into the process, it’s essential to understand what embedded system design entails. An embedded system consists of a microcontroller or microprocessor, software, and various hardware components designed to perform specific functions within a larger system. These systems are optimized for efficiency, low power consumption, and real-time performance.

Embedded systems are used in various industries, including healthcare, automotive, aerospace, consumer electronics, and industrial automation. Each application has unique requirements, such as real-time constraints, security considerations, and environmental conditions. Understanding these factors is crucial for designing a reliable embedded system solution.

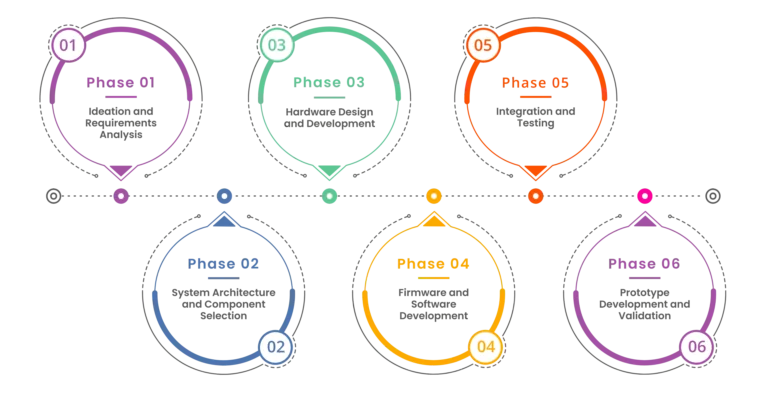

Phases of Embedded System Design: From Concept to Prototype

Phase 1: Ideation and Requirements Analysis

Every successful embedded solution begins with a clear understanding of the problem it aims to solve. The first step involves:

- Identifying the application and target users.

- Defining functional and non-functional requirements.

- Conducting feasibility studies and market research.

- Evaluating cost, power, and performance constraints.

- Identifying regulatory compliance requirements (e.g., FCC, CE, ISO, and industry-specific standards).

This phase is critical in ensuring that the final embedded system solution aligns with business and user expectations. A well-defined problem statement and requirement specification document serve as a foundation for the rest of the design process.

Phase 2: System Architecture and Component Selection

Once the requirements are set, the next step is designing the system architecture. This phase includes:

- Selecting the appropriate microcontroller or microprocessor.

- Choosing memory components, sensors, and actuators.

- Deciding on communication protocols (UART, SPI, I2C, CAN, Ethernet, etc.).

- Creating block diagrams to visualize system interactions.

- Selecting power management solutions to optimize battery life or energy efficiency.

- Ensuring cybersecurity measures are integrated into the architecture.

In 2025, many embedded designs also incorporate support for AI acceleration, 5G, and secure OTA (over-the-air) updates at the architecture level. Selecting processors that include neural processing units (NPUs) and hardware security modules (HSMs) helps future-proof designs for edge AI and security compliance.

Simulation tools such as MATLAB, LTSpice, or Proteus can help validate system design before moving to the hardware phase.

Phase 3: Hardware Design and Development

At this stage, the physical design of the embedded system solution takes shape. The key activities include:

- Designing circuit schematics using tools like Altium, KiCad, or Eagle.

- PCB layout design and signal integrity analysis.

- Prototyping using development boards such as Arduino, Raspberry Pi, or STM32.

- Component sourcing and assembling the hardware.

- Thermal and electromagnetic compatibility (EMC) testing to ensure reliability.

- Conducting Design for Manufacturing (DFM) and Design for Testability (DFT) analyses.

TinyML is also gaining traction in 2025, allowing developers to run machine learning models on microcontrollers with limited resources. Hardware selection now increasingly considers compatibility with TinyML toolchains like TensorFlow Lite for Microcontrollers.

Proper validation and testing at this stage help avoid costly errors in later phases. Engineers should perform power analysis, high-speed signal integrity checks, and stress testing to ensure the design meets operational expectations.

Phase 4: Firmware and Software Development

Firmware development is a crucial part of embedded system design. It involves writing code that controls the hardware. The main tasks include:

- Writing low-level drivers for hardware components.

- Developing real-time operating system (RTOS) applications if needed.

- Implementing power management techniques to optimize energy efficiency.

- Writing middleware and application-layer software for higher-level functionality.

- Testing and debugging using simulators, hardware debuggers, and logic analyzers.

- Securing firmware with encryption, authentication mechanisms, and secure boot.

In modern embedded designs, firmware development also involves preparing the system for AI workloads. Developers increasingly use edge AI frameworks like TVM, ONNX Runtime, and PyTorch Mobile to deploy lightweight inference models directly on the device.

Ensuring the firmware is optimized for performance and reliability is key to a successful embedded solution. Continuous integration and version control systems such as Git help maintain code quality and track changes throughout development.

Phase 5: Integration and Testing

Once hardware and firmware are ready, they need to be integrated and tested together. This phase includes:

- Unit testing individual modules to verify functionality.

- System-level testing to ensure seamless interaction between components.

- Performance testing under different operating conditions (e.g., temperature, humidity, vibration, electromagnetic interference).

- Compliance testing to meet industry standards and certifications.

- Cybersecurity penetration testing to identify and mitigate vulnerabilities.

- Implementing debugging methodologies such as JTAG debugging and in-circuit testing.

Effective debugging tools and methodologies help streamline this stage and improve the embedded system solution’s reliability. Automated testing frameworks can be leveraged to accelerate testing and reduce human errors.

Phase 6: Prototype Development and Validation

Building a working prototype is a major milestone in embedded system design. It involves assembling all components into a final prototype that resembles the production model. The prototype undergoes the following:

- Real-world testing in the intended environment.

- User feedback analysis to refine usability and functionality.

- Stress testing to determine system robustness.

- Validation against regulatory standards.

- Optimizations for manufacturability, cost, and power efficiency.

Prototyping is now aided by AI-assisted design tools, which provide suggestions for layout optimization and thermal performance. Additionally, sustainable design practices are becoming essential, including energy harvesting techniques and eco-friendly component sourcing.

Rapid prototyping methods such as 3D printing and modular development boards can accelerate this phase.

The Impact of 5G Technology on the Future of Embedded Systems

The integration of 5G technology is revolutionizing embedded system design by offering ultra-low latency, high-speed connectivity, and enhanced network reliability. This advancement enables embedded devices to operate smoothly in real-time applications, such as autonomous vehicles, industrial automation, remote healthcare, and smart cities. With the higher bandwidth and lower latency of 5G, embedded system solutions can support mission-critical applications that require instantaneous data transmission and decision-making.

Furthermore, 5G enhances machine-to-machine (M2M) communication, allowing IoT-based embedded devices to exchange data more efficiently with cloud computing resources. This improvement paves the way for AI-driven analytics, edge computing, and predictive maintenance in various industries. For example, in industrial automation, 5G-enabled embedded systems can analyze real-time sensor data to enable predictive maintenance. This helps reduce downtime and boost efficiency. As industries continue to adopt 5G, embedded engineers must optimize their designs to harness the full potential of this cutting-edge technology.

Additionally, in 2025, the convergence of 5G and edge computing is enabling decentralized embedded solutions, improving latency and enhancing intelligent decision-making at the source.

Discover More: The Impact of 5G Technology on the Future of Embedded Systems

Embedded System | 9 Main Concepts About Embedded Engineering

Understanding key concepts in embedded engineering is essential for developing robust, scalable, and power-efficient embedded solutions. These fundamental concepts help engineers design systems that meet both industry standards and real-world performance requirements.

Some of the key principles in embedded engineering include:

- Real-time Processing: Many embedded systems require real-time capabilities to ensure precise timing, such as in automotive braking systems or medical monitoring devices.

- Power Efficiency: Optimizing power consumption is crucial, especially in battery-operated embedded devices like wearables and IoT sensors.

- Memory Management: Embedded engineers must choose the right memory architecture (RAM, ROM, Flash, etc.) to balance speed, cost, and power efficiency.

- Security and Encryption: As embedded systems become more connected, implementing cybersecurity measures (such as secure boot and data encryption) is essential to prevent cyber threats.

- Scalability and Modularity: Designing systems that support future upgrades ensures long-term viability and reduces redesign costs.

- Embedded Communication Protocols: Different applications require different communication standards (e.g., UART, SPI, I2C, CAN, and wireless protocols like Wi-Fi and Bluetooth).

Additionally, engineers must be proficient in embedded programming, debugging, and testing methodologies to create highly reliable embedded system solutions. The application of these concepts ensures that embedded systems are not only functional but also efficient, secure, and scalable for future advancements.

Discover More: Embedded System | 9 Main Concepts About Embedded Engineering

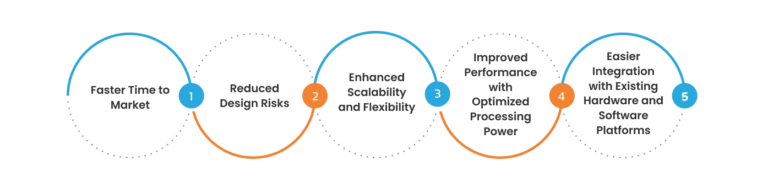

Five Reasons to Use System on Modules (SoM) in Embedded System Design

System on Modules (SoM) offers a modular approach to embedded system design, significantly reducing development time, cost, and complexity. Instead of designing a system from scratch, SoMs allow developers to integrate pre-designed computing modules with customized carrier boards. This approach provides greater flexibility, faster development cycles, and improved scalability.

Here are the top reasons why SoMs are widely adopted in embedded engineering:

- Faster Time to Market: SoMs come pre-validated with key components like processors, memory, and interfaces. This allows engineers to speed up development and focus on the application-specific features.

- Reduced Design Risks: Using a tested and certified SoM reduces the risk of hardware failures and software incompatibility. It leads to more reliable embedded system solutions.

- Enhanced Scalability and Flexibility: SoMs support a variety of processors and configurations. Making it easier to scale embedded products without significant redesigns.

- Improved Performance with Optimized Processing Power: Many SoMs integrate high-performance processors, GPUs, and AI accelerators, making them ideal for AI, robotics, and edge computing applications.

- Easier Integration with Existing Hardware and Software Platforms: SoMs provide standardized interfaces, making integrating with existing embedded solutions simpler, reducing development effort and costs.

Additionally, SoMs improve power management and thermal efficiency. This makes them suitable for applications like industrial automation, smart healthcare, automotive systems, and IoT. By leveraging SoMs, companies can future-proof their designs, adapt to changing requirements, and ensure seamless product scalability.

Discover More: Five Reasons to Use System on Modules (SoM) in Embedded System Design

Challenges in Embedded System Design

Despite advancements in technology, engineers face several challenges in embedded system design, including:

- Power Constraints: Many embedded devices operate on battery power, requiring efficient power management techniques.

- Security Risks: With the rise of IoT, embedded systems are increasingly vulnerable to cyber threats.

- Complexity Management: Integrating hardware, firmware, and software requires careful coordination.

- Cost Optimization: Balancing performance and cost is a constant challenge in embedded design.

- Time-to-Market Pressure: Rapid development cycles demand efficient project management and agile methodologies.

Green embedded design, focusing on ultra-low power operation and recyclable materials, is emerging as a key practice to address environmental challenges. Additionally, energy harvesting is a crucial aspect of this approach that helps meet sustainability goals.

Why Choose Tessolve for Your Embedded System Design Needs

Tessolve, established in 2004 and headquartered in Bangalore, India, is a leading semiconductor engineering services company. With a team of over 3,000 experts, Tessolve offers a comprehensive range of services, including IC design, IC test, PCB design, and embedded product development. Their expertise spans across industries such as automotive, avionics, data centers, industrial solutions, and semiconductors. Tessolve’s innovative solutions help clients accelerate the design and testing process, bringing next-generation products to market faster. By seamlessly aligning with the stages of embedded system design, Tessolve is well-positioned to support the development of reliable, efficient, and scalable embedded system solutions.

Let’s Sum Up

The journey from concept to prototype in embedded system design is intricate yet highly rewarding. By following a structured approach, engineers can develop reliable, efficient, and scalable embedded system solutions that meet the demands of today’s fast-paced technological landscape. Whether working on IoT devices, autonomous vehicles, or industrial automation, mastering the design process is essential for driving innovation and achieving success in these fields.

Investing in the right tools, methodologies, and industry best practices ensures that your embedded solution aligns with both industry standards and user expectations. As technology evolves, keeping up with trends like 5G connectivity and SoM is essential to stay competitive in the fast-changing field of embedded system design.