In today’s technology-driven world, embedded systems play a central role in powering everything from everyday electronics to life-saving, mission-critical applications. These systems are often the unseen backbone of aerospace, automotive safety, medical equipment, and industrial control platforms. In such high-stakes environments, safety and reliability are not just desired, they are mandatory.

What Defines a Mission-Critical Embedded System?

Mission-critical applications refer to systems where failure is not an option. A malfunction can result in significant financial loss, environmental damage, or even human fatalities. Aircraft control systems, medical life-support machines, autonomous vehicles, and military defense platforms are just a few examples where embedded systems must meet rigorous performance and safety standards.

These use cases demand not only robust embedded system design but also thorough validation, testing, and lifecycle management.

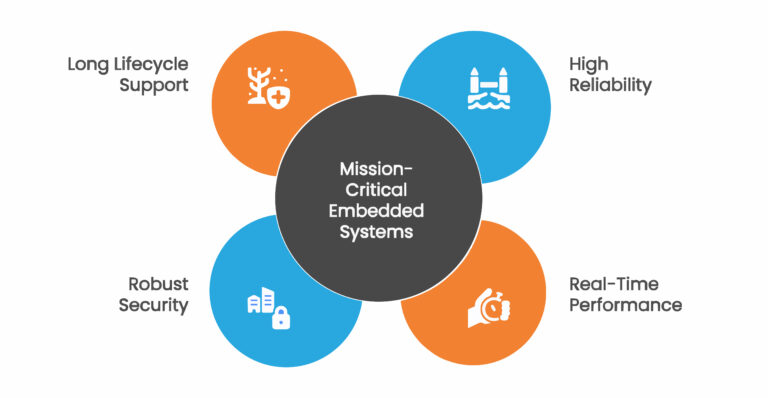

Key Characteristics of Mission-Critical Embedded Systems

To operate effectively in mission-critical roles, embedded systems must exhibit the following attributes:

1. High Reliability

These systems must perform flawlessly under a range of environmental and operational conditions. Redundancy, fault-tolerant mechanisms, and hardware-software co-design are essential to ensure consistent behavior over time.

2. Real-Time Performance

In many mission-critical domains, timing is everything. Whether it’s activating an airbag within milliseconds or adjusting a pacemaker’s rhythm, latency must be minimal and predictable.

3. Robust Security

Security breaches in embedded systems can be catastrophic. A compromised drone or a hacked medical device could lead to disastrous outcomes. Therefore, secure embedded solution architectures must be baked into the design from the outset.

4. Long Lifecycle Support

Mission-critical systems typically operate for many years, often decades. Supporting these systems long-term, including hardware obsolescence management and software updates, is crucial in the embedded system company ecosystem.

Why Safety and Reliability Matter Most

In sectors like aerospace, automotive, healthcare, and industrial automation, regulatory compliance is a fundamental requirement. Standards such as DO-178C (aerospace), ISO 26262 (automotive), IEC 60601 (medical), and IEC 61508 (industrial safety) guide the development of safe and reliable embedded products. Non-compliance is not only a legal risk but also a real-world hazard.

A single software bug in a mission-critical embedded solution could lead to loss of life, environmental disasters, or reputational ruin. Therefore, meticulous attention must be paid during the embedded system design phase, encompassing risk analysis, formal verification, hardware-in-the-loop (HIL) testing, and system validation.

The Role of Advanced Design Practices

To meet the intense requirements of mission-critical systems, developers are adopting advanced design solution strategies that combine both software and hardware innovations:

- Model-Based Design: Facilitates system simulation and validation before any physical prototyping, reducing development time and risk.

- Hardware-Software Co-Design: Enables concurrent development of software and hardware, ensuring optimized performance.

- Formal Methods: These mathematical approaches validate algorithms and safety-critical logic with absolute certainty.

- Redundant System Architecture: Designs that include multiple fail-safes and fallback mechanisms significantly enhance fault tolerance.

Such advanced design solution practices are essential for reducing time-to-market while meeting strict reliability and safety standards.

10 Essential Tips to Maximize Battery Life in Embedded System Design

Use Cases of Mission-Critical Embedded Systems

1. Aerospace

Flight control systems, satellite telemetry, and cockpit instrumentation demand fault-tolerant embedded system design with real-time processing. These systems must operate under extreme pressure and temperatures while ensuring 100% uptime.

2. Medical Devices

Life-saving equipment like ventilators, infusion pumps, and cardiac monitors relies on embedded software to function correctly and safely. The stakes in this domain are human lives, which leaves no room for error.

3. Automotive

Autonomous driving systems, ADAS (Advanced Driver Assistance Systems), and ECU (Electronic Control Units) are all powered by sophisticated embedded solution frameworks. Compliance with standards like ISO 26262 is mandatory to guarantee safety.

4. Industrial Automation

In factories and energy plants, embedded systems control machinery, monitor conditions, and prevent failures. Reliability and uptime are paramount, especially in hazardous environments like nuclear facilities or oil rigs.

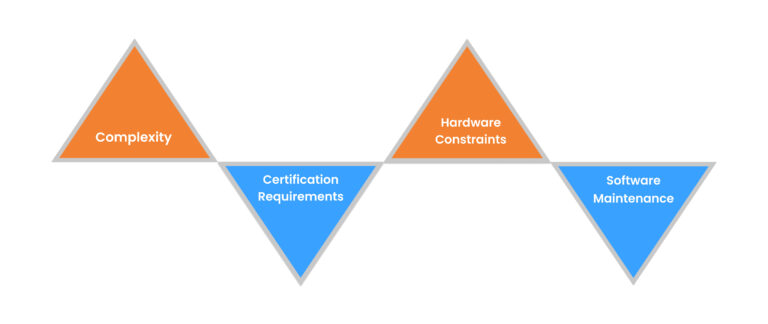

Challenges in Developing Mission-Critical Systems

Despite their significance, building mission-critical embedded systems is fraught with challenges:

- Complexity: Systems often combine multiple processors, sensors, communication protocols, and software layers.

- Certification Requirements: Compliance with industry-specific regulations demands thorough documentation and validation.

- Hardware Constraints: Low power consumption, compact design, and ruggedness must be achieved without sacrificing performance.

- Software Maintenance: Ensuring the system stays up to date without introducing new risks is a perpetual balancing act for every embedded system company.

Tessolve: Engineering Confidence into Every Embedded Solution

Tessolve understands the unique challenges of designing for mission-critical environments. As a trusted embedded system company, we bring over two decades of experience delivering cutting-edge embedded solution services to clients in aerospace, automotive, healthcare, and industrial domains.

Our approach is grounded in safety, precision, and innovation. From initial embedded system design and prototyping to regulatory compliance and long-term support, we deliver end-to-end capabilities under one roof. Leveraging our strong background in advanced design solution techniques, including model-based design, FPGA prototyping, and real-time validation, Tessolve helps customers build systems that don’t just work, they excel, even in the most demanding conditions.

Learn More: From Concept to Prototype: The Complete Embedded System Design Process

Conclusion: Building Trust Through Reliability and Safety

In a world increasingly reliant on automation and smart systems, the importance of trustworthy embedded systems cannot be overstated. For mission-critical applications, where failure is simply not an option, embedded system design must go beyond innovation to include resilience, predictability, and verifiability.

Whether it’s a ventilator in an ICU, a controller in a space shuttle, or a self-driving car, embedded systems are shaping the future of safety and reliability. Organizations that invest in robust embedded solution architectures, adhere to safety standards, and work with experienced partners like Tessolve are better positioned to lead in their industries.

The path to high-assurance embedded systems is not easy, but it is essential. It calls for a holistic approach combining advanced design solution strategies, continuous validation, and long-term commitment. With the right expertise and execution, companies can transform challenges into opportunities and build mission-critical systems that stand the test of time.