The rise of Industry 4.0 is transforming the way industries manufacture, monitor, and deliver products. Smart factories now rely on interconnected systems that demand instant decision-making and minimal downtime. At the heart of this transformation are real-time embedded systems, which integrate hardware and software to deliver deterministic responses in critical operations. Unlike traditional computing, these systems guarantee predictability, precision, and reliability. From robotics and predictive maintenance to automotive safety and healthcare devices, they are indispensable. As Industry 4.0 accelerates, the need for robust embedded system design and collaboration with a trusted embedded system company has never been greater.

What Are Real-Time Embedded Systems?

A real-time embedded system is a microprocessor-based system designed to perform specific tasks within strict timing constraints. It can sense, process, and respond to inputs in fractions of a second, ensuring that delays do not compromise functionality.

Examples of their deployment include:

- Industrial robots for precise assembly and welding

- IoT-enabled smart sensors in factories

- Autonomous vehicles ensuring road safety

- Medical devices like pacemakers and infusion pumps

- Aerospace and defense applications

The essence of real-time performance lies in determinism, delivering predictable results, even under heavy workloads. This requires specialized hardware, carefully engineered software, and advanced scheduling techniques.

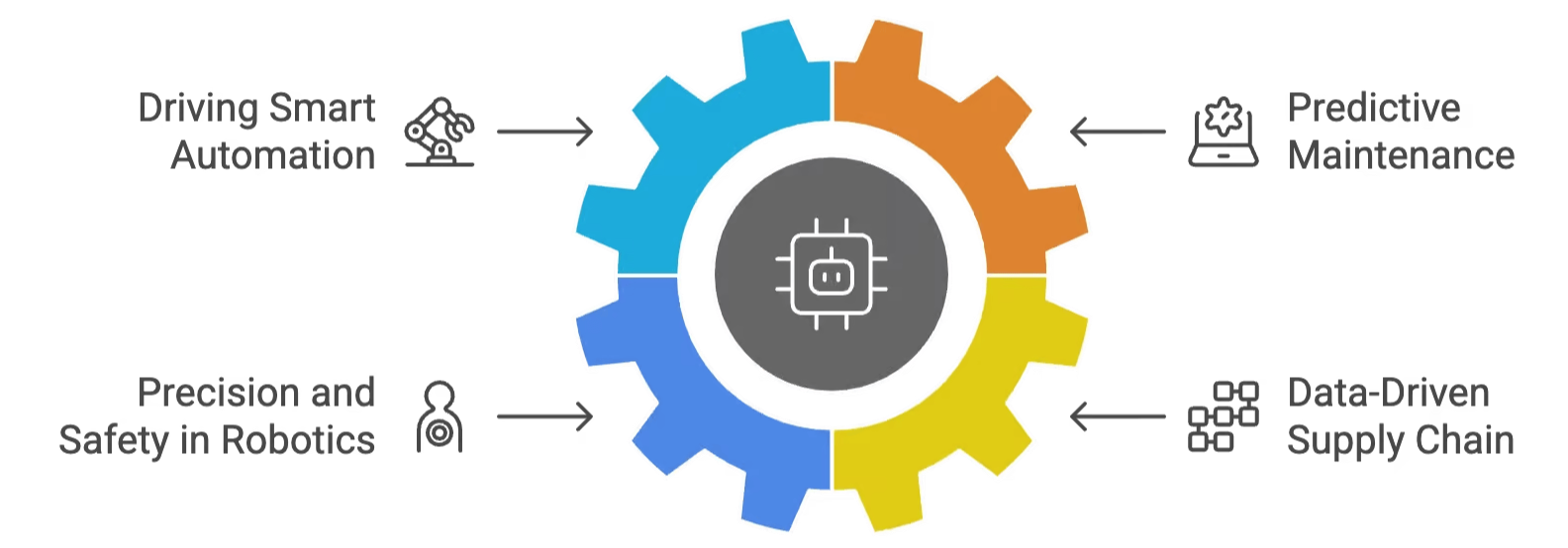

Importance of Real-Time Embedded Systems in Industry 4.0

1. Driving Smart Automation

Automation in Industry 4.0 relies on embedded solutions that can monitor sensors, analyze inputs, and actuate machinery in real time. A delay of even milliseconds could impact product quality or worker safety.

2. Predictive Maintenance

Embedded systems equipped with vibration, temperature, and pressure sensors predict equipment failures before they occur. This reduces unplanned downtime and ensures higher operational efficiency.

3. Precision and Safety in Robotics

Collaborative robots, or cobots, operate alongside humans on factory floors. Real-time controls prevent accidents and allow robots to execute tasks with microsecond-level precision.

4. Data-Driven Supply Chain

From warehouses to transport fleets, embedded systems provide real-time visibility into goods movement. They enhance supply chain transparency and support just-in-time operations.

Key Features of Real-Time Embedded Systems

To meet Industry 4.0’s demands, real-time systems must demonstrate certain critical features:

- Deterministic Behavior: Guaranteed response time to inputs, regardless of system load.

- Connectivity: Integration with industrial communication protocols such as OPC UA, PROFINET, and Time-Sensitive Networking (TSN).

- Power Optimization: Techniques such as duty cycling and adaptive scaling for energy efficiency.

- Safety Compliance: Adherence to international safety standards such as ISO 26262 and IEC 61508.

- Security by Design: Secure boot, firmware authentication, and encrypted communications built into the system.

Each of these capabilities relies heavily on skilled embedded system design to ensure reliability in high-stakes environments.

Why Real-Time OS is Critical for Next-Gen Industrial IoT Devices

Challenges in Building Real-Time Embedded Systems

Designing systems for Industry 4.0 is not without challenges:

- Ultra-Low Latency: Achieving responses within sub-millisecond ranges across devices.

- Cybersecurity Threats: Protecting interconnected systems from intrusion or tampering.

- Integration with Legacy Equipment: Ensuring new technologies can work seamlessly with older industrial systems.

- Scalability: Building solutions that grow with expanding operations.

- Compliance Burden: Meeting strict safety and quality certifications without delaying time-to-market.

These challenges demand the involvement of an experienced embedded system company that can deliver an advanced design solution combining technical depth and compliance expertise.

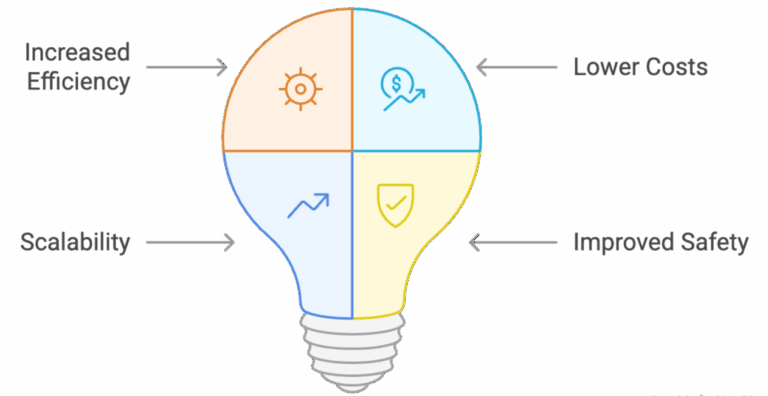

Benefits of Effective Embedded System Design

A well-executed embedded system design brings transformative benefits to Industry 4.0 operations:

- Increased Efficiency: Reduced downtime and improved machine utilization.

- Lower Costs: Predictive maintenance and power efficiency reduce operational expenses.

- Scalability: Modular designs that expand easily to support new technologies.

- Improved Safety: Fault-tolerant mechanisms and fail-safe operations.

- Better Insights: Real-time data collection drives intelligent decision-making.

For enterprises embracing Industry 4.0, these benefits are a competitive advantage that accelerates digital transformation.

Role of Embedded System Companies in Industry 4.0

A reliable embedded system company plays a pivotal role in bridging the gap between concept and deployment. Their contributions include:

- End-to-End Engineering: Covering hardware prototyping, firmware, and system integration.

- Testing and Validation: Ensuring compliance with international safety and performance standards.

- Advanced Analytics: Integrating edge AI for smarter decision-making.

- Lifecycle Management: Supporting products beyond launch with maintenance and updates.

Such partnerships provide an advanced design solution that accelerates product readiness while minimizing risk.

Future Outlook for Real-Time Embedded Systems

The evolution of Industry 4.0 is closely tied to advancements in embedded technology. Future innovations include:

- AI at the Edge: Embedding intelligence directly into devices for faster, localized insights.

- 5G and Ultra-Reliable Networks: Enabling ultra-low-latency communication for industrial automation.

- Digital Twins: Real-time embedded systems powering simulations that mirror factory operations.

- Sustainability: Energy-efficient embedded solutions supporting green manufacturing goals.

As industries move forward, businesses that embrace cutting-edge embedded system design and collaborate with capable embedded system companies will secure a competitive edge.

Real-Time Embedded Systems and Cybersecurity in Industry 4.0

As industries become more connected, cybersecurity has become a critical factor in embedded technologies. Real-time systems often control mission-critical equipment, making them prime targets for cyberattacks. A secure embedded system design integrates encryption, authentication, and intrusion detection at the hardware and software levels. Companies must ensure that over-the-air updates, access control, and identity management are part of the deployment strategy. Partnering with an experienced embedded system company ensures that security is not just an afterthought but a core component of an advanced design solution, protecting industrial operations from costly disruptions.

Why Tessolve Is the Right Partner for Industry 4.0

Tessolve offers over 20+ years of expertise in semiconductor and embedded systems engineering to help industries accelerate their journey towards Industry 4.0. Our expertise spans silicon design, validation, hardware platforms, and embedded software, giving us the ability to deliver complete advanced design solutions tailored to real-time applications. Through our Embedded Systems and Software Labs, we provide system-on-modules (SOMs), evaluation kits, wireless connectivity, automotive firmware, and AI-optimized embedded designs for industrial deployments. With a strong global presence, we go beyond being an embedded system company; we are your partner in creating reliable, secure, and future-ready solutions.