System Level Test

Ensuring every product component reaches its full potential through unified, real-world simulation

Ensuring every product component reaches its full potential through unified, real-world simulation

Optimize device classification & yield improvement with flexible, software-driven binning strategies that adapt to diverse testing requirements.

Extend test socket lifespan, reducing replacement costs and ensuring consistent performance over multiple cycles.

Prevent costly errors from double stacking and misalignment, enhancing system integrity during testing.

Enables automated retesting of devices over time to monitor performance and identify defects.

Supports testing across a wide temperature range, simulating real-world conditions.

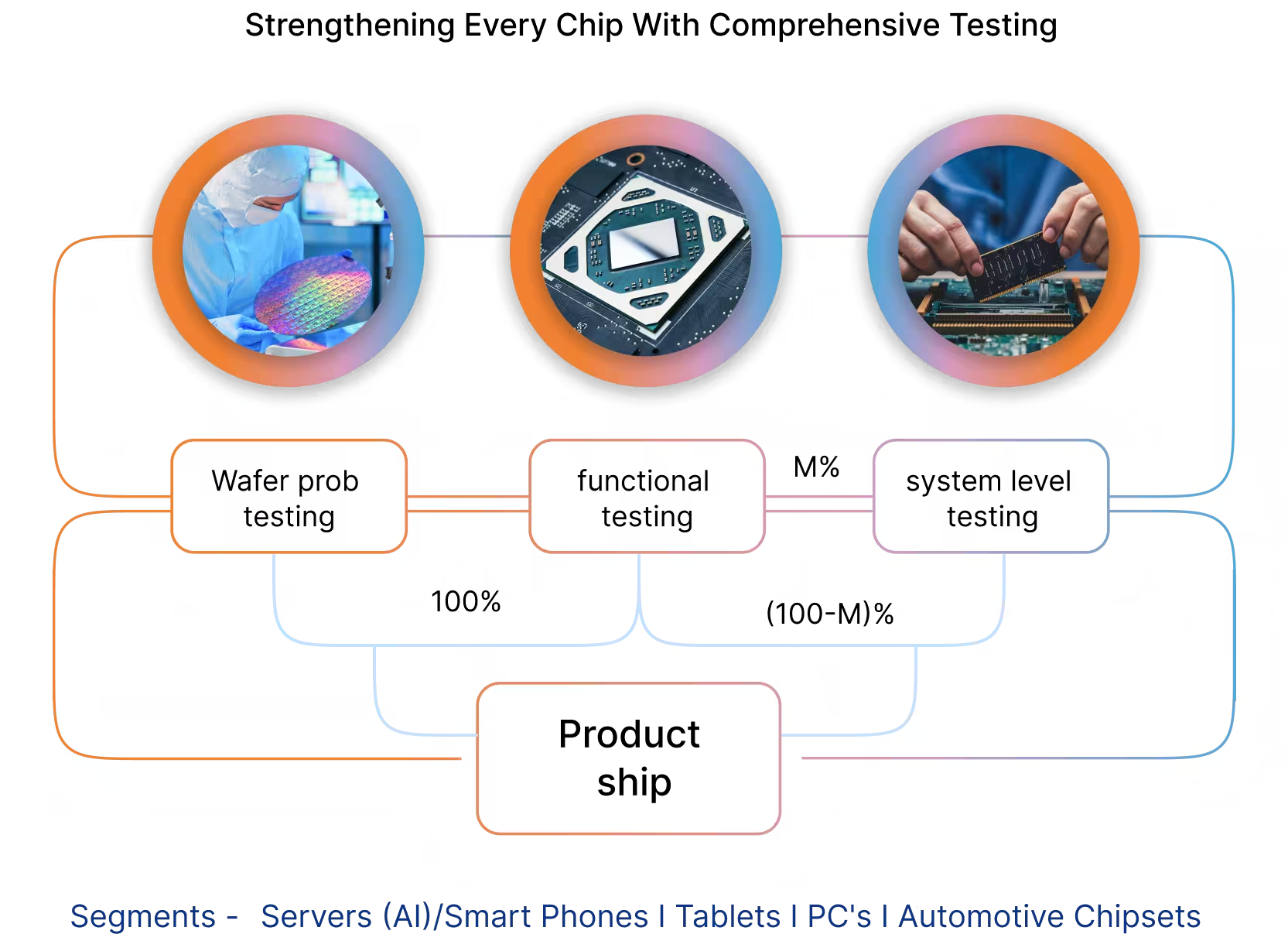

Recognizing the value of SLT methodology, our clients have integrated it throughout their testing processes to improve test coverage and production quality, especially for mission-critical applications. This approach replicates real-world operating conditions of devices, ensuring a vital step in the production

testing of complex systems-on-chip (SoCs).

System-level testing for smartphones, tablets, and PCs to ensure optimal performance and reliability.

Automation frameworks, libraries, and foundational concepts for streamlined testing processes.

Complete validation of the design flow aligned with the proposed architecture.

Support and evaluation during the layout phase for enhanced design accuracy.

Extensive technical support to address all testing and design needs.

Automated pick & place system ideal for engineering samples.

Accommodates a Wide range of chip sizes for smartphones, tablets, PCs, and automotive chipsets.

Operates efficiently across a temperature range from ambient to 125℃.

Compact size and low cost per test site for expandable applications.

Graphical interface (Windows) for quick and easy device setup.

Experience the power of our System Level Test (SLT) services, where we streamline system-level testing through adaptable hardware setups. Our reference hardware configurations—whether standalone, bench, or handler—enable seamless automation, ensuring that testing is both efficient and effective. This versatility allows us to gather precise data that monitors the health of your custom silicon products, ensuring they meet rigorous performance and reliability standards. By leveraging these tailored configurations, you can trust in our ability to deliver actionable insights, accelerate your development cycle, and enhance your product’s overall quality in a competitive market.

Allows for automated testing of multiple units

Provides environmental control (thermal)

Generates standardized data formats for analysis

Enables in-depth system behavior analysis under different conditions